In production of composite (polymer-sand) products not only sand can be seen as filler, but also crushed glass, porcelain, pottery, etc.

"Polimerstroy18" Production Company produces crushers for glass and other materials within the range from small mobile solutions to stationary high-performance crushers for industrial use.

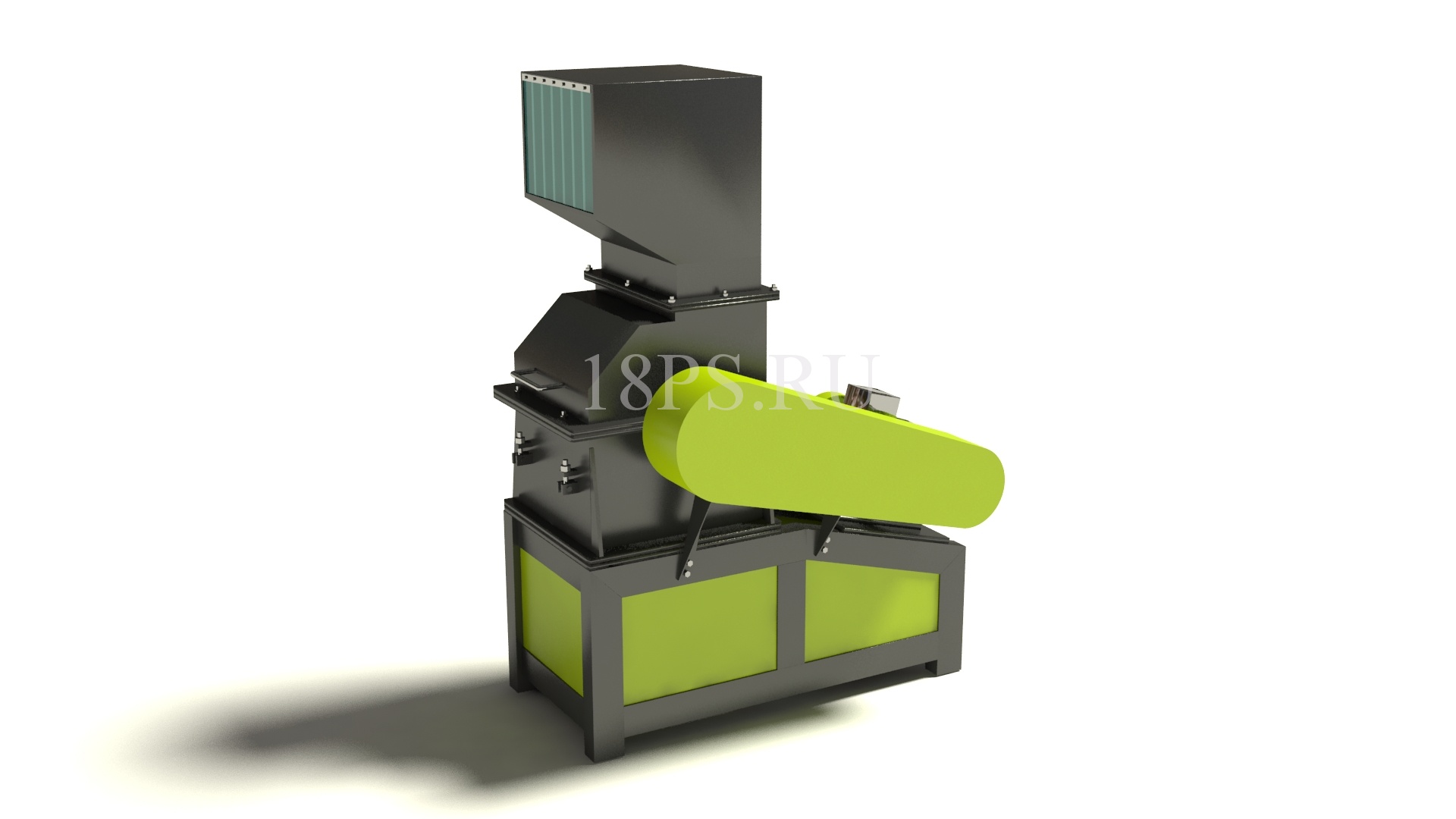

Glass Impact Crusher IMS-500

Rotary glass impact crusher refers to a mechanism, wherein grinding is performed due the impact of working bodies and the material. The spinning roll is fitted with oscillating hard-alloy plates - hammers. Due to high kinetic energy of the hammers (weight and rotational speed) the crusher easily crushes glass. Movable hammers eliminate roll jamming during crusher operation. This type of crusher is characterized by high economical and technological characteristics. The advantages of impact crushers include small size, high efficiency, and stable operation. Impact crusher design is simple and reliable; the service process will not be difficult as there are no parts that require periodic sharpening.

Optional equipment designed according to customer’s specifications, in standard version.

1. Receiving hopper;

2. Storage hopper;

3. Support racks etc.

4. Transportation systems:

Conveyor, screw, elevator.

This equipment may be needed to feed the crusher, and also to transport the crushed material to the desired distance.